Customization

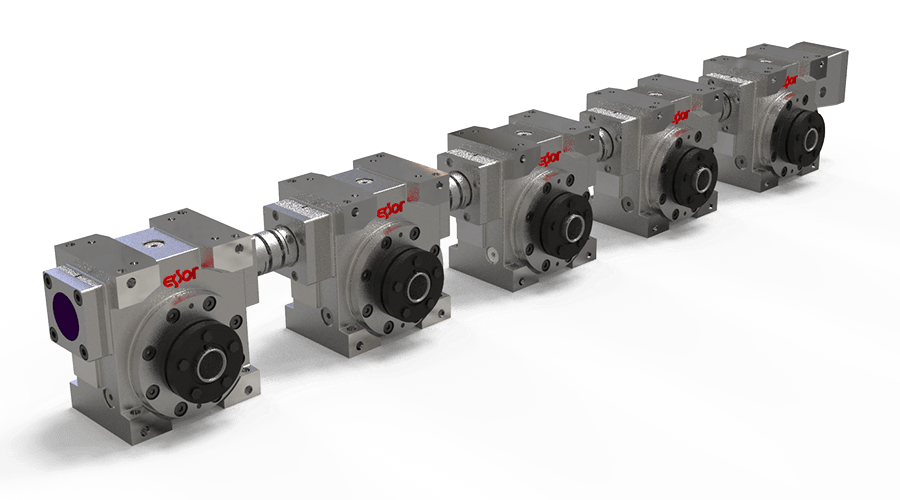

Product Introduction

Customization

Essor has accumulated both experiences in theory and in practice as a result of long-time collaboration with Taiwanese universities since the beginning up till now. We collaborate with doctorate professors of mechanical engineering from Taiwan to design and develop worms, worm gears and worm reducer systems for customized requirements.

Essor grasped the experience and knowledge from various gear theories, such as harmonic drives, bevel gears and helical gears to secure a up-to-date technology and to manufacture high precision worm related products.

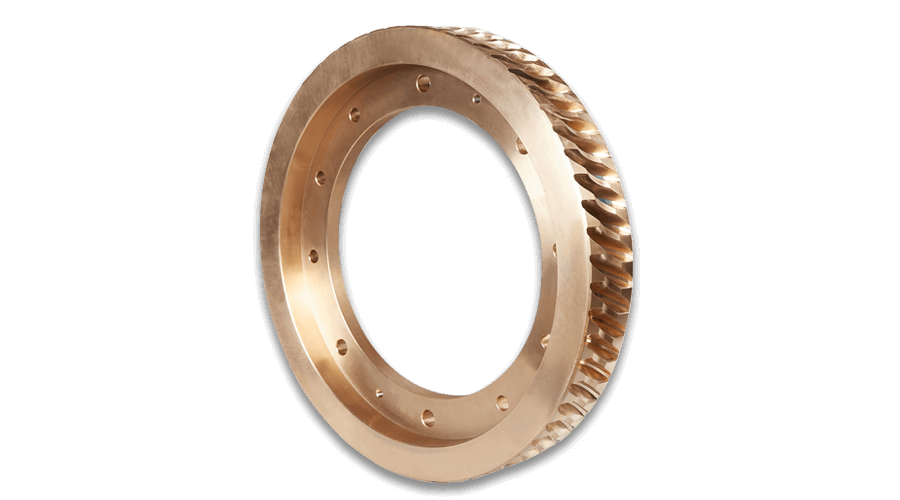

How to make high precision worm gears? We emphasize on high quality equipment such as gear cutters, hobbing machines and gear measuring machines. Based on the experience of being gear cutters agent for more than 20 years, Essor understands the crucial role of high quality cutters in worm gears cutting. Liebherr gear cutting machines and Klingelnberg gear measuring machine are our strong backups for quality assurance. We invested heavily from the start in order to offer such products as the same quality level of Siemens from Germany. It was very challenging for a small-scale company to have such a heavy investment since the beginning, but it was a correct and essential decision to be made. It requires vision and courage. However, we were able to accomplish this goal and it made us one of the best worm and worm gear manufacturers in China.

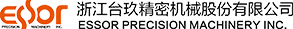

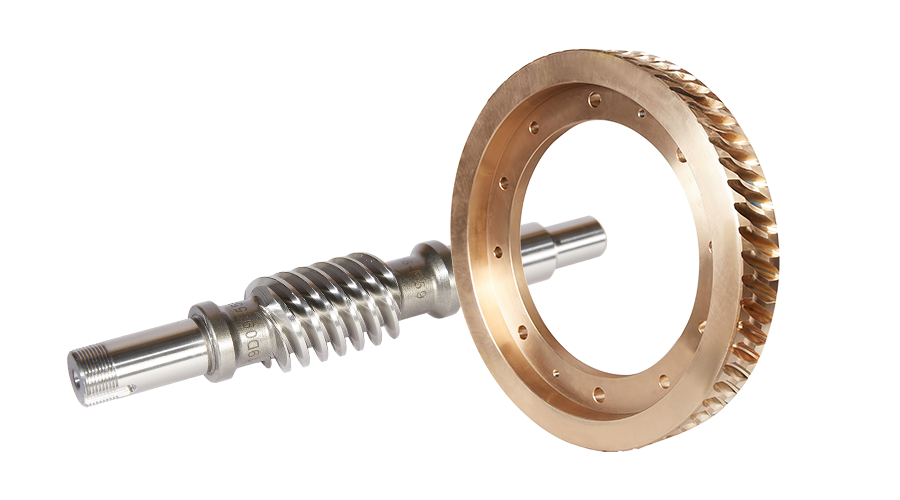

How to make a good worm reducer? Worm, worm gear and housing are the key components for a high-standard worm reducer. All the vital parts mentioned above must be in outstanding quality, otherwise, it is impossible to make a worm reducer with backlash down to one arc minute. Assembly is another important issue that will affect the quality of a worm reducer as well.

We implemented stringent procedures of machining and assembly quality control from the beginning. The worm reducers we supplied are in high quality only.

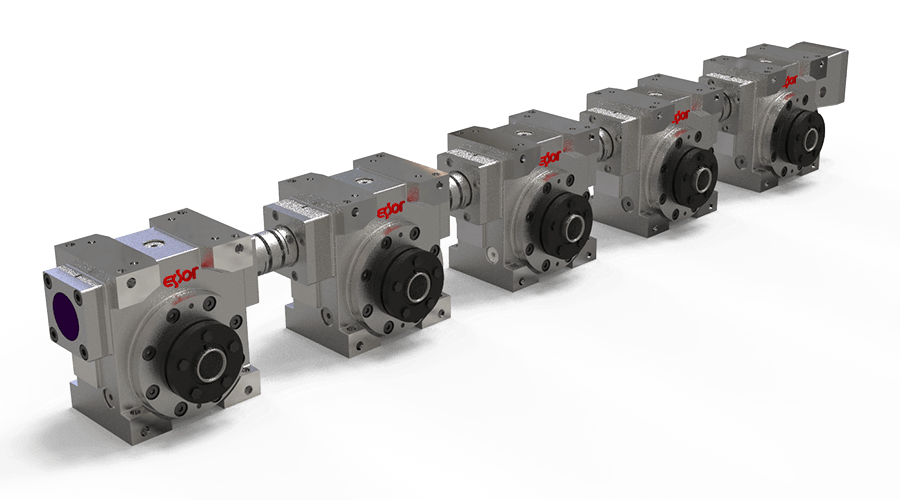

The customized products offered by Essor are applied in various domains. For example, we produce worm reducers for maintenance-free dual lead azimuth drives for heliostat as well as dual lead worm drives for mobile phone glass polishing machine with synchronous output of 5 worm reducers of which backlash is almost zero.

We are specialized in providing total solution for customers with complete worm reducers or simply worm and worm gear units . There will be a completed project management processes controlled including feasibility study, development schedule arrangement, calculation, design, prototype construction, test, pilot production and mass production.