About us

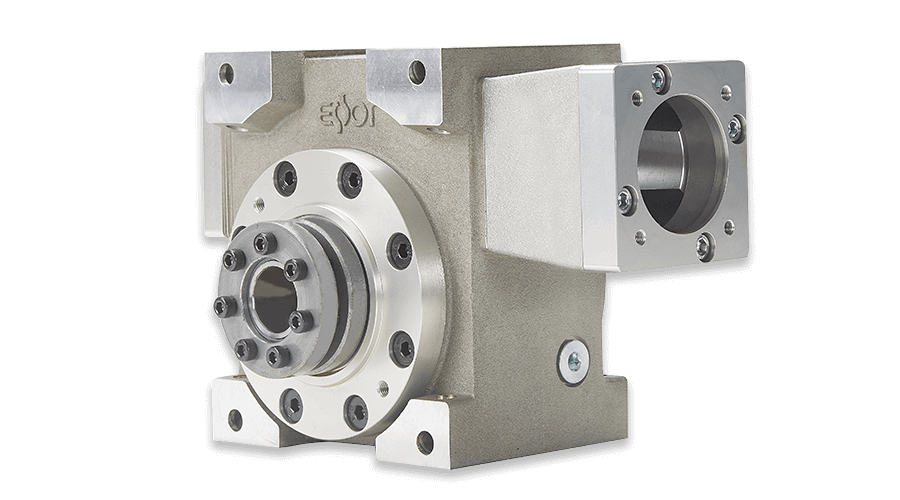

Powered by tireless dedication and innovative ideas, P&P Drive as well as ESSOR PRECISION MACHINERY INC. see themselves as solution provider to customers who require customization design or simply wish to have products made according to their drawings.

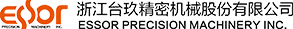

Thanks to stringent requirements, guidance and audit from Siemens as well as high quality equipment from Germany, we were able to learn and grew rapidly through failures and mistakes. Based on all these good or bad experiences, Essor has accumulated expertise in manufacturing high precision worms and worm gears for various applications especially in rotary tables, machining automations, electric actuators, escalators, elevators, spinning pumps, folding carton die cutting machines and heliostat drives, etc.

The best precision for our product is up to DIN 2.

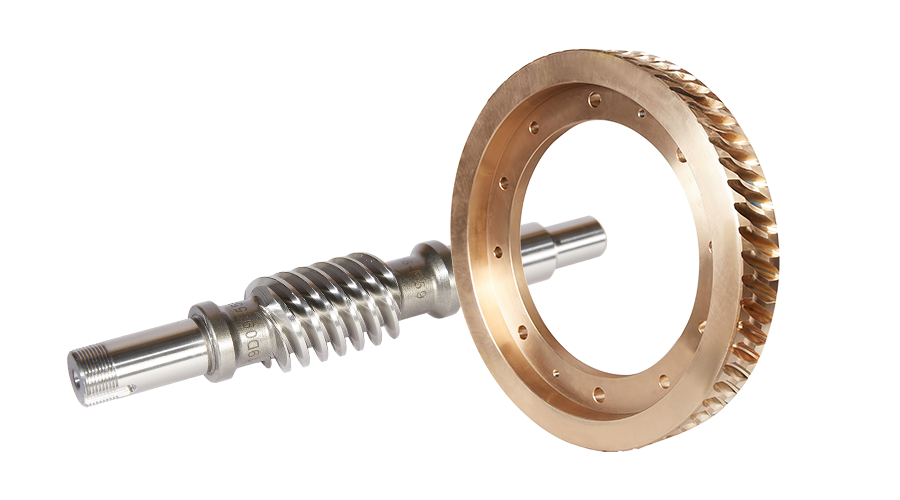

In the short history of worm, worm gear and complete drive system manufacturing, the products and services portfolio of Essor focuses on niche market of high precision requirements. We pay attention to every detail from the beginning to delivery and aim to achieve highest customers’ satisfaction and quality service.

With the right marketing positioning, product positioning and competition positioning, Essor has gained reputation in the Niche market.

Essor has been continuously working on technological innovation and project management control to optimize customers’ requirement and satisfaction. We are one of the best worm and worm gear/wheel makers in China. If you are looking for a supplier with European quality standard and competitive prices, we are your best choice.

We strictly control production quality especially for material and heat treatment. Every product has its ID number for tracing. Whenever customers relay any quality query with ID number, we can easily and instantly trace the records and make the correct response.

Performing etching test after worm grinding is our standard procedure to check whether the tempering layer is formed on tooth surface or not, the tempering layer will reduce hardness. This is the procedure requested by Siemens.

Topological diagram produced by gear measuring machine is to build a master and compare the mass production parts with master to check if contact patterns are good enough or not. It is important to assess contact pattern correctly and objectively by topological diagram instead of meshing machine with blue high spot indicator.

Our quality control is according to VDA6.3 standard, which is requested by Siemens; Siemens hosts annual audit regularly. We are also ISO 9001:2015 certified by TÜV.

We ensure an on-time and defect-free delivery for customers with high level of integration and coordination among our quality department, technical department, processing department and outsourcing department.We ensure an on-time and defect-free delivery for customers with high level of integration and coordination among our quality department, technical department, processing department and outsourcing department.